Enhancing Water Pump Quality Control: Best Practices in Precision Manufacturing for Water Pumps

Enhancing Water Pump Quality Control: Best Practices in Precision Manufacturing for Water Pumps

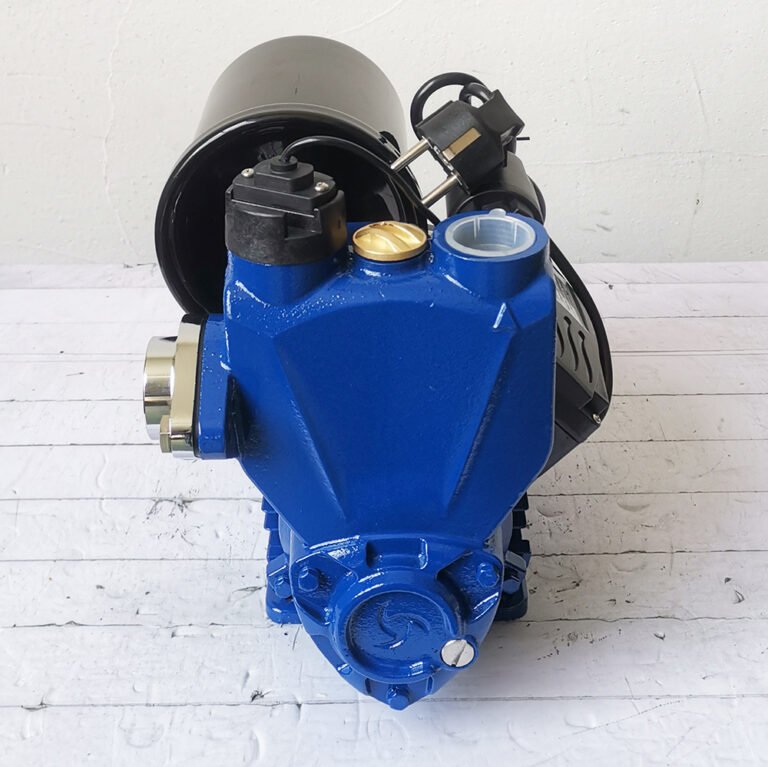

In today’s competitive market, maintaining superior quality is vital in industrial water pump production. At Weijind Water Pumps Company, we are dedicated to excellence through a comprehensive quality control system that underpins our advanced water pump production techniques. In this post, we explore our best practices in water pump quality control and how we achieve precision manufacturing for water pumps.

1. Material Selection and Initial Testing

Every high-quality water pump begins with selecting premium raw materials. Our process starts with rigorous testing to ensure that all materials meet the highest standards for durability and performance. By implementing high precision water pump inspection procedures, we guarantee that only the best materials are used in the production process. This step is essential for laying a strong foundation for the entire manufacturing process.

2. Precision Manufacturing Techniques

Achieving precision manufacturing for water pumps means integrating state-of-the-art machining and fabrication methods. Our production process utilizes advanced CNC machining, robotic assembly, and computer-controlled quality checks. These techniques allow us to produce components with exact tolerances, ensuring a perfect fit during assembly and optimal operational efficiency. This commitment to precision manufacturing not only reduces waste but also enhances the overall reliability of our water pumps.

3. Automated Testing and Quality Control

An integral part of our strategy is the use of automated water pump testing systems. After assembly, each water pump undergoes rigorous testing under simulated operating conditions. These tests include:

- Hydrostatic pressure tests to validate the strength and leak-proof nature of the pump casing.

- Flow rate and efficiency measurements to ensure that the pump meets design specifications.

- Vibration analysis to detect any mechanical imbalances.

These water pump inspection procedures help us maintain consistency and optimize our water pump production process optimization efforts. By catching potential issues early, we can prevent defects and enhance product longevity.

4. Continuous Improvement and Process Optimization

At Weijind Water Pumps Company, we view quality control as an ongoing process. We continually refine our production methods by analyzing test data and incorporating feedback from both our technicians and customers. This dedication to continuous improvement drives our commitment to water pump quality control and supports our mission to deliver high-performance products that exceed industry standards.

Conclusion

Investing in robust water pump quality control and precision manufacturing for water pumps is key to success in today’s market. Our integrated approach—from meticulous material selection to advanced automated testing—ensures that every pump we produce stands up to rigorous industry demands. For more details on our manufacturing process and to explore our range of reliable water pumps, please visit www.kxhweijing.com.

Our Product Range:

We serve various industries both domestically and internationally. Our range of water pumpproducts includes:

- Peripheral pumps

- Centrifugal pumps

- JET self-priming pumps

- Self-suction pumps

In addition, we manufacture for water pump and accessory such as peristaltic, progressing cavity, screw, and gear pumps. This enables us to provide multiple solutions for your processes and accommodate almost any fluid.