SDP Series Close coupled 2-stage Industrial Centrifugal Pumps

- SDP Series Close coupled 2-stages End-suction Industrial Centrifugal Pumps

- Category: INDUSTRIAL PUMPS

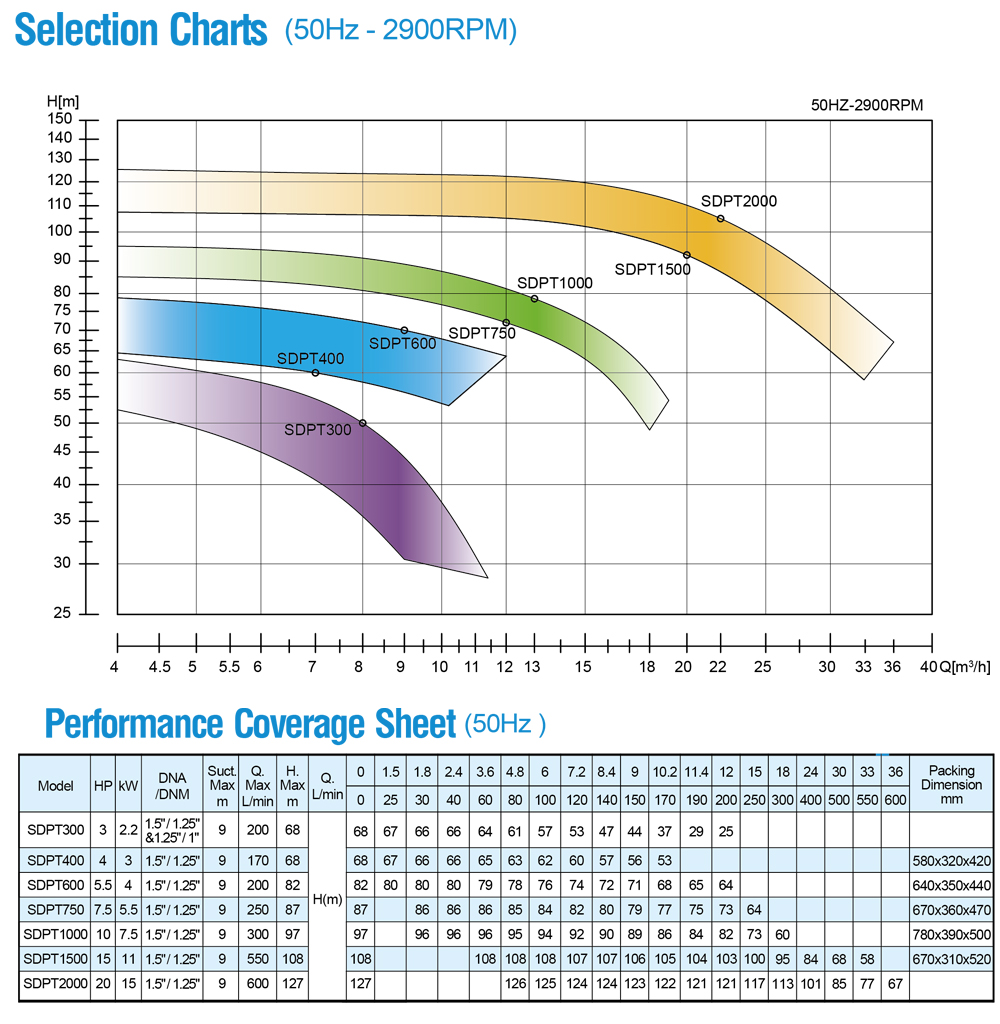

- 4HP~20HP

- 3kw~15KW

- Max.flow:600L/min

Description

Introduction to 2-Stage Industrial Centrifugal Pumps

The 2-Stage industrial centrifugal pumps are a type of twin impeller centrifugal pump designed for use in pressurization units for domestic, civil, and industrial applications. These pumps are suitable for a wide range of water supply applications, including sprinkling irrigation, well-pumping, water supplying, decanting, domestic water supply, pressure boosting for high buildings, garden and agriculture irrigation, and industrial use.

Features of 2-Stage Industrial Centrifugal Pump

The 2-Stage industrial centrifugal pumps offer several key features that make them suitable for various applications:

- Difference compact appearance for household and industrial use

- Close-coupled twin-impeller design

- Long-life robust construction for durability

- Special configuration could be upgraded on request

- Capable of clean water transfer

- Suitable for domestic water supply and pressure boosting for high buildings

- Ideal for garden and agriculture irrigation as well as industrial use

Singe-stage VS 2-Stage Centrifugal Pumps

Industrial centrifugal pumps come in two configurations: single-stage and 2-stage. 2-stage pumps feature two impellers on a shared shaft, each with a single eye. These pumps can operate in two modes: capacity (parallel) and pressure (series). When deciding between these configurations, the initial consideration should be whether a single-stage or 2-stage pump is required.

Single-stage pumps lack transfer valves or internal flapper valves to direct water flow, resulting in fewer moving parts. This leads to lower manufacturing costs, reduced maintenance, and less required operator training. Conversely,2-stage pumps offer greater versatility and efficiency at higher pressures, making them well-suited for specific applications.

The operational modes determine how the pump impellers function. Single-stage pumps excel at higher flow rates but are less efficient at higher discharge pressures. In contrast,2-stage pumps, with their ability to handle high pressure/low volume or high volume/lower pressure scenarios, are favored by some departments for firefighting applications.

When high fire flow rates are essential, a single-stage pump may be the preferable option. However, if high pressures are necessary to move water through long lays of small diameter hose (such as in wildland scenarios) with lower flow rates, then a two-stage pump might be more suitable. Some departments opt for two-stage pumps due to their ability to handle both high pressure/low volume and high volume/lower pressure situations.

More the case solution and the style selection kindly contact us highly appreciated.