SEN Series Monoblock Horizontal Industrial Centrifugal Pump

- Product Item : SEN Series Monoblock Horizontal Industrial Centrifugal Pumps

- Category: INDUSTRIAL PUMPS

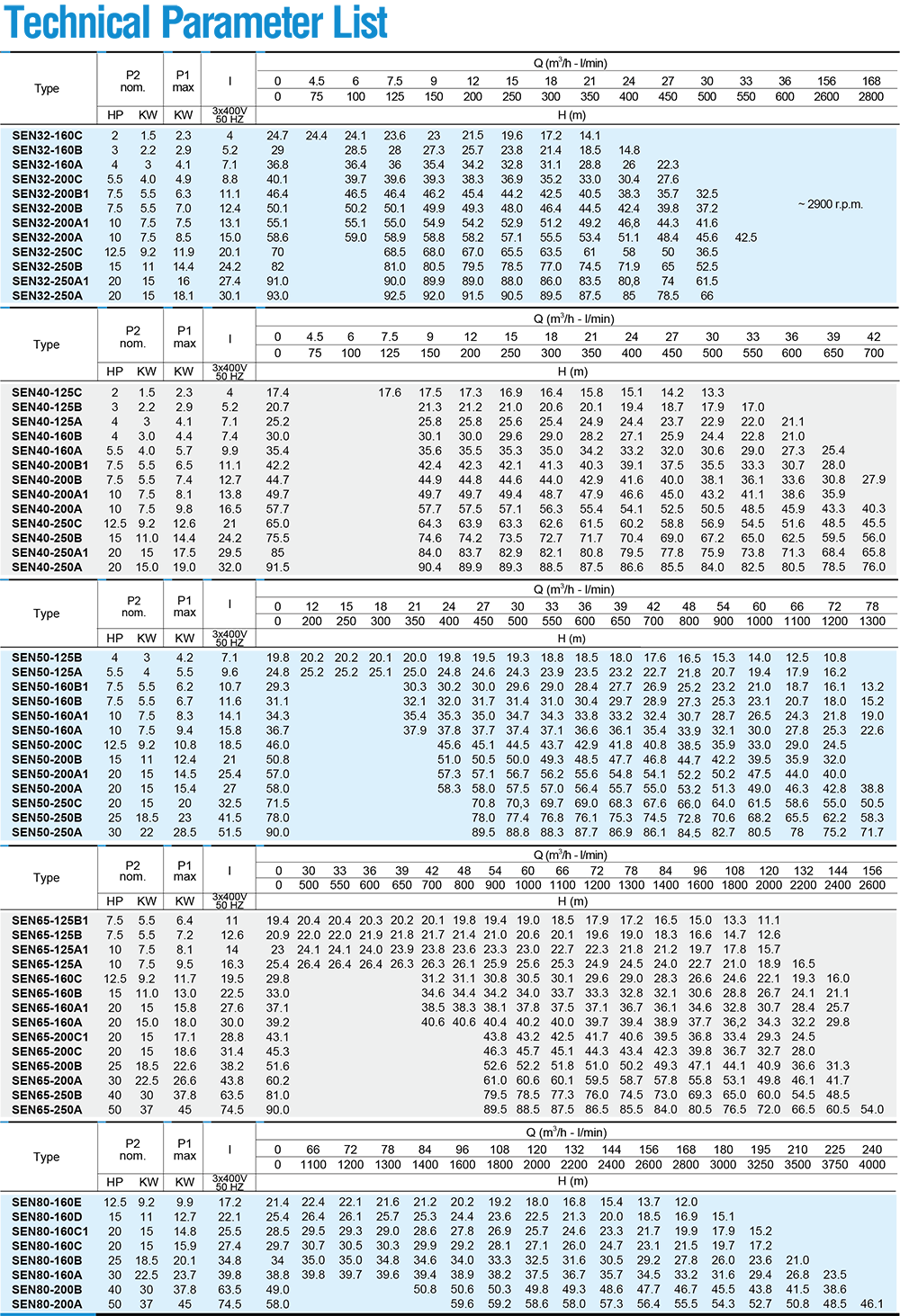

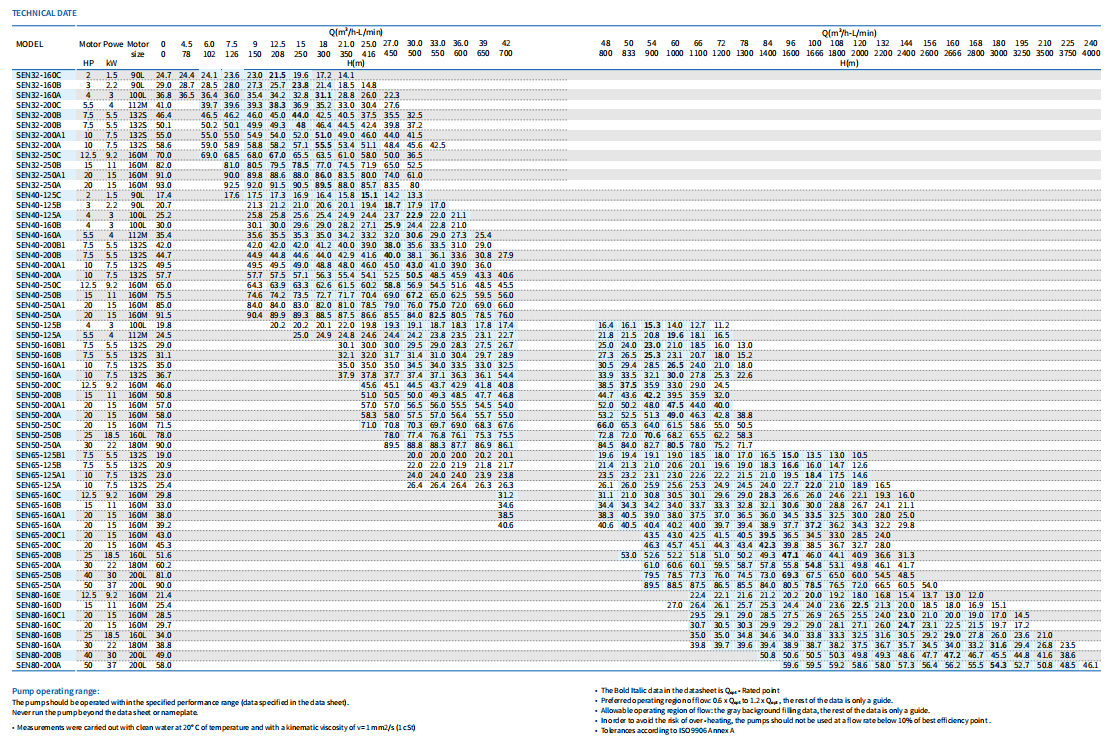

- 2HP~50HP

- 1.5kw~37KW

- Max.head:58m

- Max.flow:4000L/min

- Max.Allowable Working Pressure(MAWP):10 bar

- Working temperature Range:-10°C~+90°C

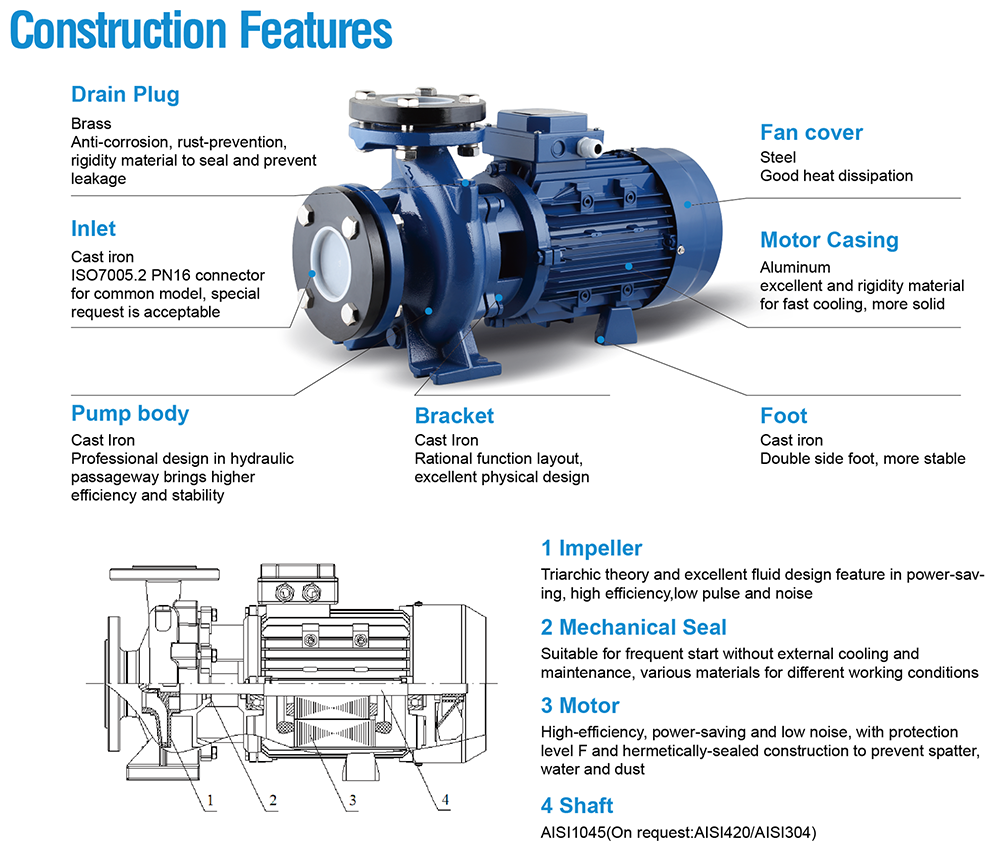

Description

Introducing the SEN Series Monoblock Horizontal Industrial Centrifugal Pump

The SEN Series Monoblock Horizontal Industrial Centrifugal Pump is a reliable and efficient solution for various industrial applications. With its advanced design and high-quality construction, which could be widely used for household and industry. Especially, building water supply, cooling circulation, firefighting system, water works, industrial HVAC system, and water-saving irrigation.

Product summary of this Horizontal Industrial Centrifugal Pump

•Can pump a wide range of clean low viscosity or slightly contaminated fluids

•Close coupled compact centrifugal design to combat space limitations

•Back pull-out design to ensure quick and easy maintenance

•Maximum fluid temperature of 140°C

•Independent pump and motor shafts

•Available in cast iron, 316 stainless steel, duplex stainless steel, bronze and other materials upon request

•Suction and discharge flanges conform to EN 1092-2 / PN 16. Flanges according to EN 1092-1 / PN 16 for steel and stainless steel casings. If required, ANSI/ASME flanges can be supplied.

•Single phase and three phase 50hz / 60hz motors. IP55 as standard.

•Independent certification is available upon request

•Manufactured in accordance with standard

•Available is horizontal and vertical configuration

•Casing wear rings to prolong casing and impeller life

•Can be supplied with an air powered or electric priming pump

Benefits and Efficient for this Horizontal Industrial Centrifugal Pump

The compact horizontal design with close coupling ensures the pump’s installation in areas with limited space. The back pull-out design facilitates motor removal while the pump remains connected to the piping, enhancing service and maintenance efficiency.

The centrifugal pump and motor feature separate shafts, enabling only the pump shaft to be replaced if damaged. In contrast, some less robust horizontal centrifugal pumps rely solely on the motor shaft, necessitating motor replacement upon shaft failure.

A lantern bracket positioned between the pump and motor creates a protective barrier, shielding the motor from fluid ingress in the event of a seal malfunction.

Additionally, wear rings can be installed in the pump head as sacrificial components. These rings endure wear first, safeguarding the impeller and casing from premature deterioration, thereby extending the lifespan of these parts and ultimately the pump itself.

Furthermore application,

The horizontal industrial centrifugal pump and vertical centrifugal pump is also available in an ATEX version for handling flammable fluids or being installed in a non-safe area.

If required, the XCN close coupled horizontal centrifugal pump can be supplied with an external air powered or electric priming pump for applications where a suction lift is unavoidable.

We provide not only water pumps, but solutions for the users.

Our products include submersible pumps, surface pumps and circulation pumps, covering a wide range from household, agricultural, commercial to industrial areas. Futhermore, we are committed to providing solutions for different applications, not only on single products but also on more comprehensive solutions for the customers:

- Peripheral pumps

- Centrifugal pumps

- JET self-priming pumps

- Self-suction pumps

About us: the SERVICES:

- Customized design according to samples, drawings, and performance requirements.

- With over 20 years of skilled experience, we offer OEM exporting services tailored to your needs.