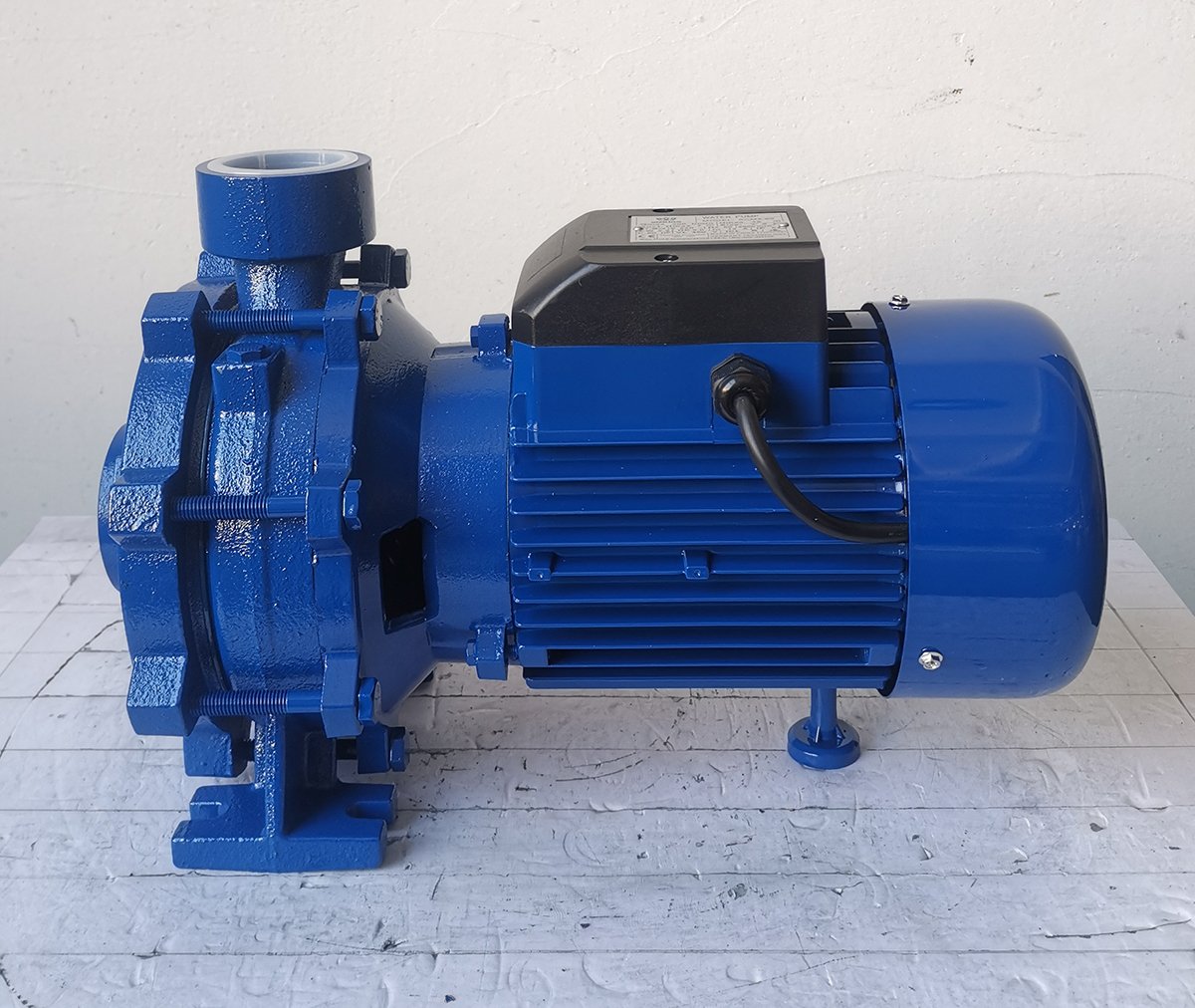

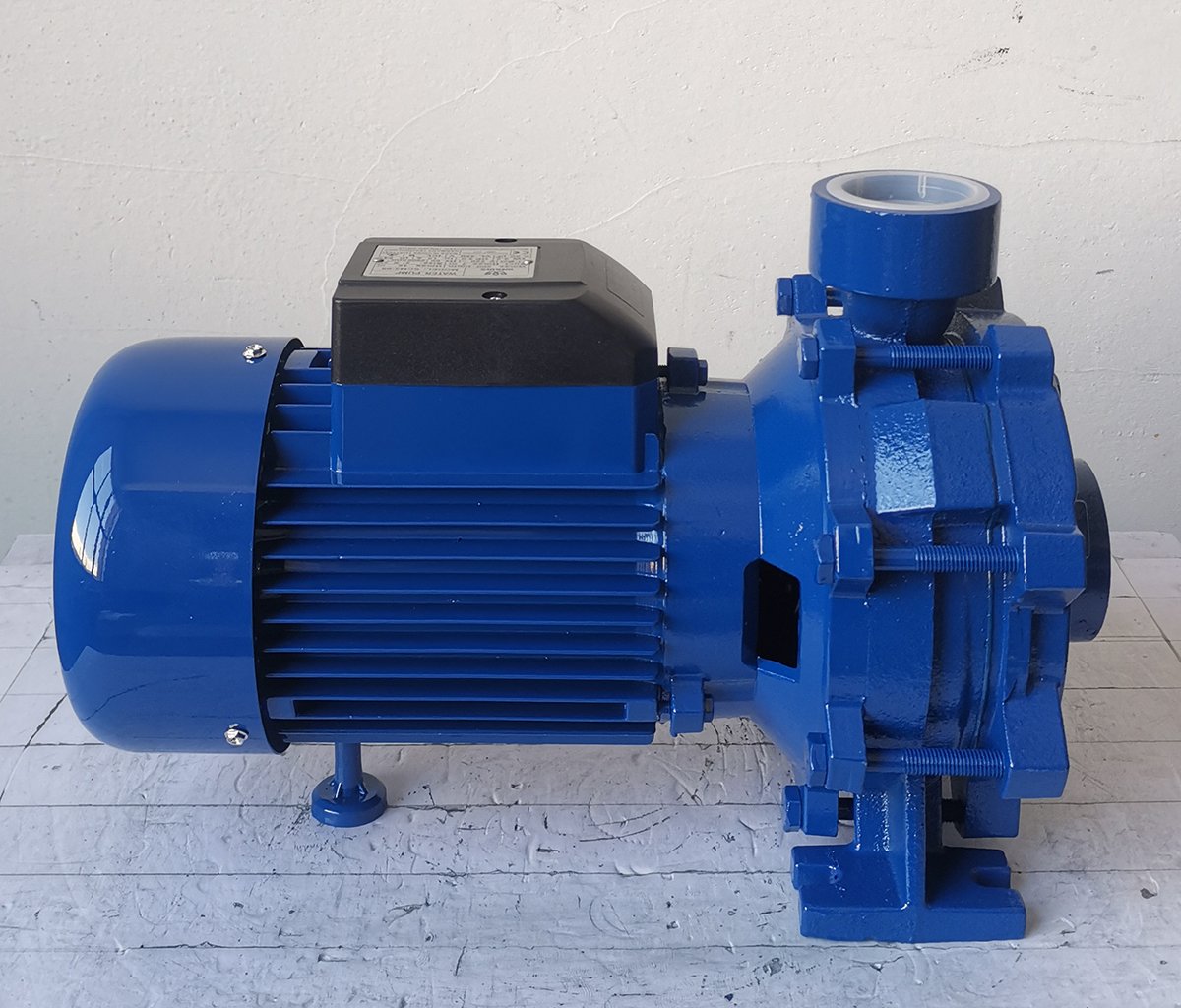

SCM2 Series Two Stage Centrifugal Pump

- Product Item : SCM2-45,SCM2-52,SCM2-55,SCM2-60

- Category: CENTRIFUGAL PUMPS

- 1HP–3HP

- 0.75KW–2.2KW

- Max.Head.m:55m

- Max.Q.L/min:140L/min

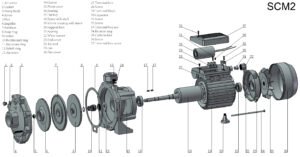

Construction Materials

.Pump body:cast iron

.Motor housing:aluminum

.Motor:closed, externally ventilated

.Impeller:brass

.Insulation:B/F

.Duty:continuous rated

.Mechanical Seal:steatite ceramic/metalized carbon

Description

Features and Specifications of SCM Series Two Stage Centrifugal Pump

The SCM2 Series two stage centrifugal pump stands out due to its meticulously engineered twin impeller design.

For domestic use, the SCM2 Series pump proves to be an invaluable asset in ensuring a consistent and reliable water supply. Its design is tailored to handle the pressures and flow rates required for household water systems, from filling storage tanks to maintaining water pressure for daily use. This adaptability makes the SCM2 Series pump a practical choice for homeowners seeking an efficient and durable water pumping solution.

Overall, the SCM2 Series two stage centrifugal pump, with its twin impeller design, combines efficiency, reliability, and versatility. Whether for commercial, agricultural, or domestic applications, it offers an economical and safe solution for clean water environments, solidifying its reputation as a dependable and practical choice for a wide array of pumping needs.

Operating Conditions and Construction Materials of the SCM2 Series

The SCM2 Series two stage centrifugal pump is designed to operate efficiently under a range of conditions, ensuring its versatility and reliability in various applications.

Application

.Gardening

.Agriculture irrigation

.Domestic water tank architecture

Working conditions

.Maximum ambient temperature up to +40℃

.Maximum fluid temperature up to 80℃

.Maximum pressure up to 10 bar

The twin impeller design features brass impellers, which are resistant to corrosion and wear, making them ideal for handling various fluids without degradation. The mechanical seal, made from steatite ceramic and metalized carbon, provides a robust seal that prevents leaks and withstands the rigors of continuous operation. These materials collectively ensure that the SCM2 Series pump is not only durable but also reliable for long-term use in myriad environments, from industrial settings to residential applications.

FAQ on/about Two Stage Centrifugal Pump:

-What is the difference between single stage and two stage centrifugal pumps?

Well, the two-stage pump outperforms the single-stage across the board: it matches capacity under 200 PSI, excels at 200 to 300 PSI, and boasts high-pressure capacity of over 400 PSI, whereas the single-stage falls short at less than 300 PSI.

– What are the main reasons to use the two stage pump?

The two-stage pump offers dual benefits compared to one or three-stage pumps. Firstly, it enhances fluid displacement speed. Secondly, it efficiently handles viscous fluids like oil and gas, a feat unmatched by one or three-stage pumps. Two primary variants exist: positive displacement and centrifugal pumps.

Please Meet Us: We provide not only water pumps, but Water Pumping Solution Centrifugal Pumps for the users.

Our range of products includes:

- Peripheral pumps

- Centrifugal pumps

- JET self-priming pumps

- Self-suction pumps