Vertical Multistage Centrifugal Pump Water Pumps

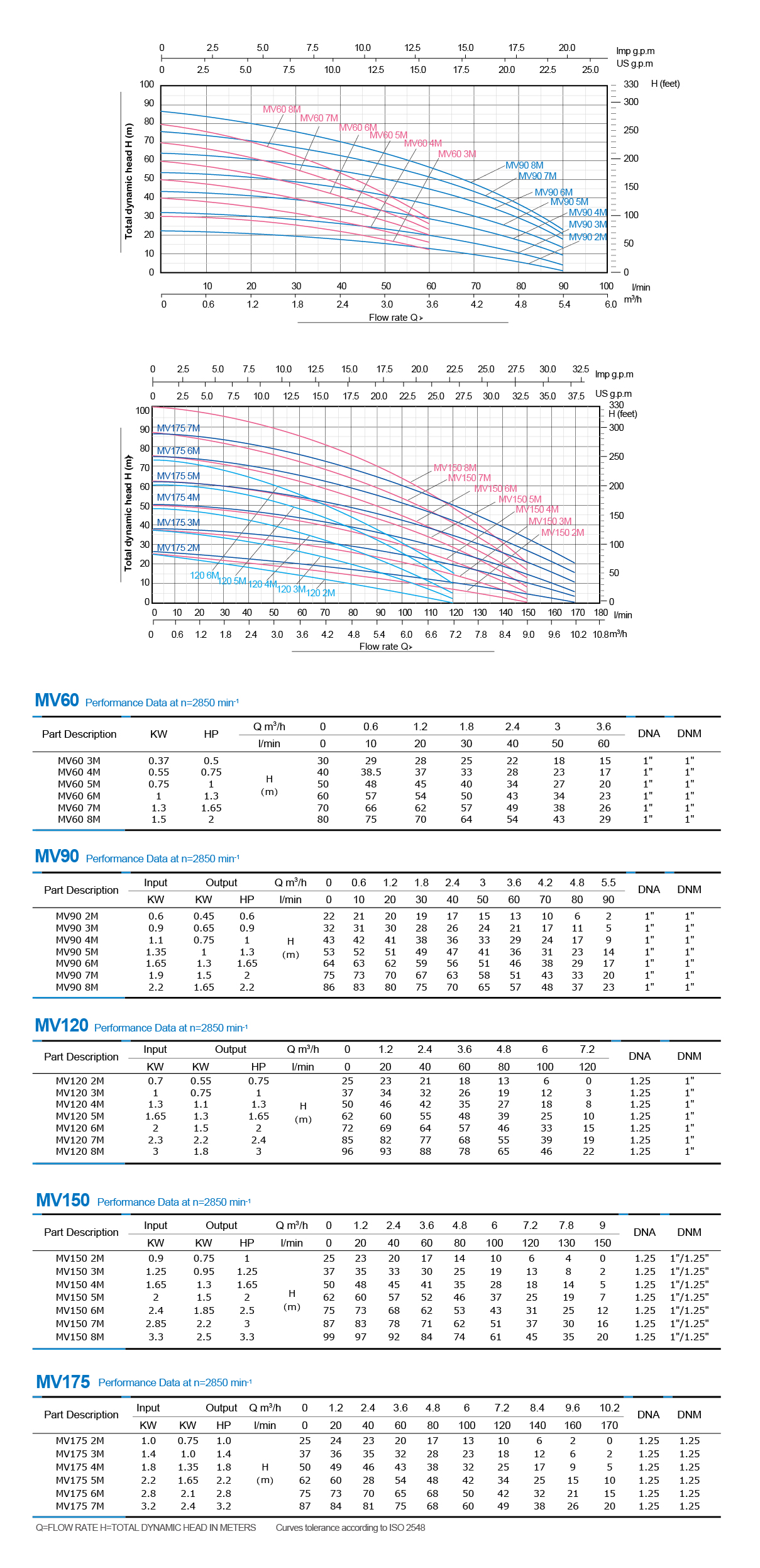

- Product Item : MH/MV60 Multi-stage Centrifugal Pump

- Category: MULTI-STAGE CENTRIFUGAL ELECRTIC PUMPS

- 0.6HP–2.4HP

- 0.37kw–1.5KW

- Impeller quantity:3–10pcs

- Max.flow: 60L/min

Description

Introduction to Vertical Multistage Centrifugal Pump

When it comes to efficient pumping of clean water across various applications, the vertical multistage centrifugal pump stands out as an industry frontrunner. With its compact design and low-noise operation, this pump is an ideal solution for water transfer, drip irrigation, sprinkler systems, and domestic water boosting. The MV series excels in delivering outstanding performance, ensuring reliable water pumping with minimal noise. Its space-saving configuration makes it a sturdy and efficient choice for different water pumping needs.

Whether employed in irrigation, drip systems, or household water boosting, the MV series stands out for its exceptional performance in a vertically efficient and quiet design.

Features of Vertical Multistage Centrifugal Water Pumps

The vertical multistage centrifugal pump comes with a range of features that make it a reliable and efficient choice for various applications:

- Self-priming up to 6m

- Stainless steel housing and cataphoresis coating for anti-rust and durability

- Silent running and high efficiency performance

- Flow rates up to 365l/min

- Head pressure up to 13bar

- Multi-materials for different applications

- Dry-run protection for 1 phase construction materials

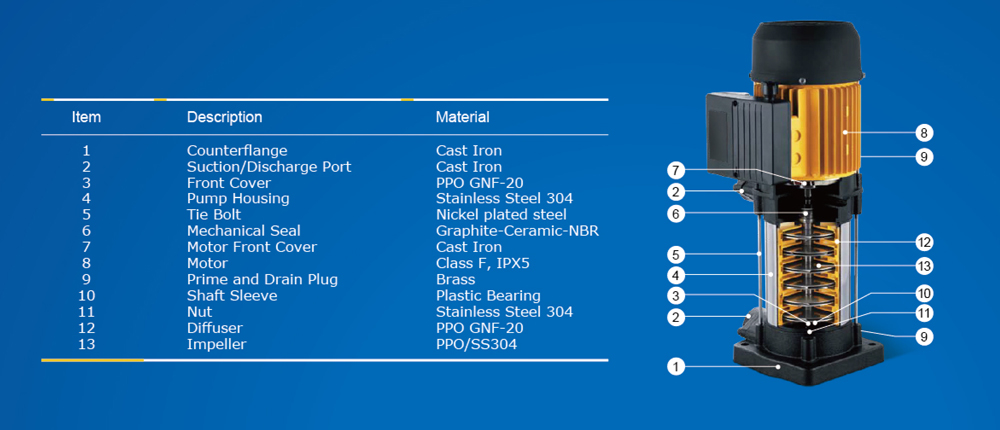

The construction materials of the Multistage Centrifugal Pump include:

- Pump body: Stainless steel

- Motor housing: Aluminum

- Motor: Closed, externally ventilated

- Diffuser: PPO

- Impeller: PPO/Stainless steel

- Insulation: B/F

- Duty: Continuous rated

- Mechanical seal: Steatite ceramic/metalized carbon

Applications of Vertical Multistage Centrifugal Pump

The vertical centrifugal multistage pump can be utilized for a wide range of applications in the industrial and marine markets. It is designed to pump low viscosity clean or slightly contaminated fluids without the presence of solid or fibrous particles. Common fluids pumped include fresh water, sea water, and fuels such as diesel, petrol, and kerosene. The pump finds applications in various sectors including:

- Boiler feed

- Chemical and energy plants

- Mining

- Firefighting

- Reverse osmosis

- Water treatment

- Pressurization

- Dewatering

- Building systems

- Marine and cooling/heating conditioning (HVAC)

- Petroleum

- Irrigation and water supply

The vertical multistage design offers several benefits, including:

- Various options for flange configurations, making it versatile for installation on sites with difficult pipework layouts

- Vertical compact design for sites with space limitations

- Multiple closed impellers and diffusers to achieve very high pressures

- Maximum casing pressure of 63bar

- Fitted with sacrificial wear rings, protecting the casing and impellers from premature wear

Product Summary

Summarily, the vertical multistage centrifugal pump offers the following features and specifications:

- Can pump a wide range of clean low viscosity fluids

- Various flange configurations with the suction and discharge flanges available on the side, on top, or on opposing sides

- Vertical compact multistage design

- Maximum fluid temperature of 140°C

- Independent pump and motor shafts

- Fitted with sacrificial wear rings, which are replaced periodically

- Available in cast iron, 316 stainless steel, duplex stainless steel, bronze, and other materials upon request

- Independent certification is available upon request

- Manufactured in accordance with standard ISO

- All impellers are balanced according to ISO

- Long coupled with baseplate

- Bearings are greased

- Can be supplied with an air-powered or electric priming pump