Optimizing Water Pump Production Efficiency: Best Practices for Enhanced Quality Control in Water Pumps

Optimizing Water Pump Production Efficiency: Best Practices for Enhanced Quality Control in Water Pumps

In today’s competitive water pump market, achieving high production efficiency while maintaining strict quality standards is essential. At Weijind Water Pumps Company, our commitment to an advanced water pump manufacturing process ensures that every pump we produce meets the rigorous demands of modern industry and wholesale buyers. In this post, we explore best practices that optimize water pump production efficiency and enhance quality control in water pumps.

1. Streamlining the Advanced Water Pump Manufacturing Process

The foundation of an efficient production system starts with a well-designed advanced water pump manufacturing process. By leveraging modern CNC machining and automated assembly lines, we reduce production time and minimize errors. This systematic approach not only improves water pump production efficiency but also contributes to consistent product quality that meets the expectations of our domestic buyers and wholesale partners.

2. Implementing Rigorous Quality Control in Water Pumps

Quality control is paramount in our production cycle. We utilize comprehensive quality control in water pumps measures, including:

- Real-Time Inspection Systems: Automated sensors monitor each stage of production, ensuring that all components adhere to strict quality standards.

- Detailed Performance Testing: Each pump undergoes hydrostatic pressure and flow rate testing to guarantee optimal performance.

- Continuous Improvement Feedback Loops: Feedback from our testing phases is integrated into the manufacturing process, promoting continuous improvement and higher product reliability.

3. Leveraging Data for Enhanced Water Pump Production Efficiency

Data-driven decision making is a critical part of modern manufacturing. Our production system utilizes real-time analytics to monitor key performance indicators such as cycle time, defect rate, and energy consumption. By optimizing these metrics, we enhance water pump production efficiency while reducing costs and waste. This approach not only benefits our internal processes but also delivers better value to our industrial water pump wholesale customers.

4. Benefits for Domestic Buyers and Wholesale Partners

Optimizing the manufacturing process and reinforcing quality control translates directly into tangible benefits:

- Increased Reliability: Consistent product quality means fewer failures and less downtime for end-users.

- Competitive Pricing: Improved efficiency lowers production costs, enabling us to offer competitive prices in the domestic market.

- Enhanced Customer Trust: A robust advanced water pump manufacturing process ensures that each pump meets the exacting standards required by industrial buyers and wholesalers, fostering long-term business relationships.

Conclusion

Optimizing water pump production efficiency and enforcing stringent quality control in water pumps are key drivers of success in today’s competitive market. At Weijind Water Pumps Company, our integrated approach to manufacturing and quality assurance guarantees that our products not only perform reliably but also provide superior value to our domestic water pump buyers and wholesale partners. For more information about our products and production practices, please visit www.kxhweijing.com.

We serve various industries both domestically and internationally. Our range of water pumpproducts includes:

- Peripheral pumps

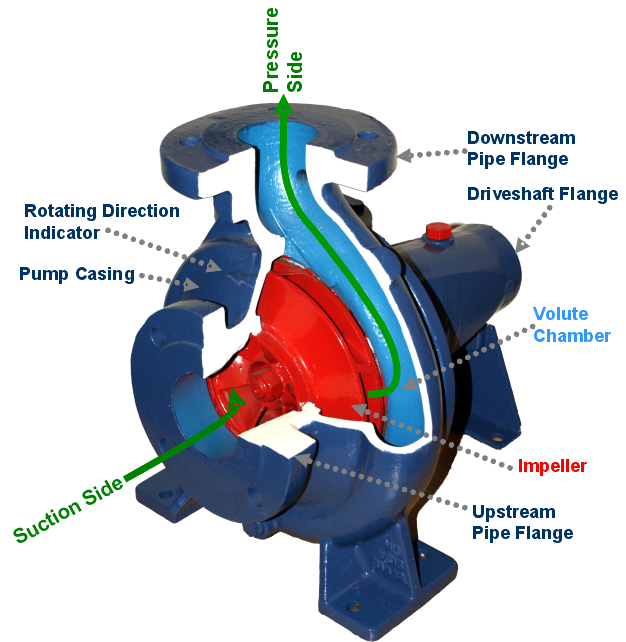

- Centrifugal pumps

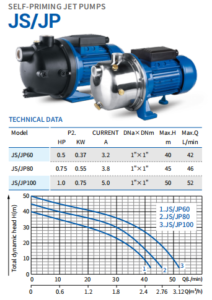

- JET self-priming pumps

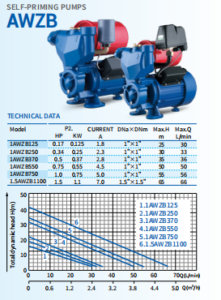

- Self-suction pumps

In addition, we manufacture for water pump and accessory such as peristaltic, progressing cavity, screw, and gear pumps. This enables us to provide multiple solutions for your processes and accommodate almost any fluid.